What Are You Looking For?

What Are You Looking For?

In the HVAC industry's pursuit of energy efficiency, sustainability, and cost-effectiveness, insulation emerges as a crucial component.

In the HVAC industry's pursuit of energy efficiency, sustainability, and cost-effectiveness, insulation emerges as a crucial component. This article examines the technical aspects of insulation in HVAC systems, particularly in fan coil units, and explores advanced manufacturing techniques and solutions to common challenges.

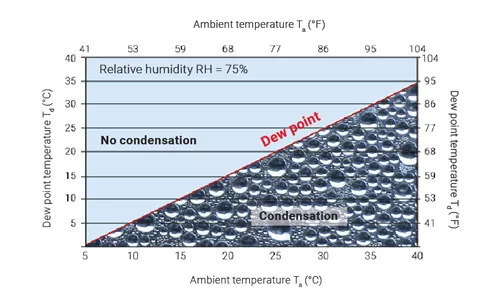

Insulation plays a vital role in HVAC and refrigeration systems, primarily for condensation and temperature control. When equipment operates below ambient air temperature, moisture can condense or freeze on cold surfaces, leading to corrosion and reduced efficiency.

Common insulation materials for HVAC systems include:

Critical properties for selection:

| Material | WVTR (Perms) | Thermal Conductivity (Btu/hr-ft-°F) | Fire Retardancy Rating |

|---|---|---|---|

| Fiberglass | 0.5 - 1.0 | 0.25 - 0.35 | Class A (self-extinguishing) |

| Polyurethane | 0.1 - 0.2 | 0.20 - 0.25 | Class B

|

| Elastomeric Foam Rubber | 0.03 - 0.05 | 0.19 - 0.24 | Class A |

Extrusion Process Optimization:

Automated Cutting and Fitting:

The concept of "economic thickness" is crucial in insulation selection. It represents the insulation thickness that minimizes the combined cost of heat loss and installed insulation.

Factors to consider:

As we discussed in the previous article, which provided a detailed examination of "insulation economics," the optimal insulation level may need to be adjusted based on safety considerations, not just economic grounds.

The strategic selection and application of insulation materials significantly impact the efficiency and longevity of HVAC equipment. By leveraging advanced manufacturing techniques, addressing key challenges, and embracing technical innovations, HVAC manufacturers can optimize their products' performance and maintain a competitive edge in the evolving industry landscape.

As the industry progresses, the role of insulation in driving efficiency, sustainability, and cost-effectiveness will become increasingly vital. Understanding and implementing these technical and economic considerations will be crucial for manufacturers aiming to deliver high-performance, energy-efficient, and environmentally responsible HVAC solutions.

As a leading manufacturer of high-performance closed-cell elastomeric foam insulation, Hairui directly addresses the key HVAC challenges discussed in this article. Our advanced solutions, leveraging rubber-making techniques and raw materials, optimize energy efficiency, prevent condensation, and enhance overall system performance, making us your ideal partner in elevating HVAC technology.

Ready to optimize your HVAC systems with advanced insulation technology? Contact Hairui today to explore how our multi-layer systems and custom-molded components can enhance your products' efficiency and compliance.

Get a Free Consultation with Our HVAC Insulation Experts and Elevate Your Manufacturing Process Now.